You might already be familiar with sump pumps (or a sump basin) in your own homes. These devices are designed to collect, manage, and remove excess water before it can cause damage to your property. But have you heard of sump sinks? Although their function is quite similar to that of a sump pump, sump sinks serve a unique purpose in the food service industry.

In this article, we’ll explore the specific applications of sump sinks, compare different materials, and introduce an IMC product that could help enhance your setup. Let’s dive in.

### What Exactly Is a Sump Sink?

When it comes to the food service industry, sump sinks—also known as floor drains—are additional troughs installed beneath primary sinks. Their role is to efficiently filter out leftover water from your facility. Sump sinks are typically found under compartment sinks, dish tables, worktables with built-in sink bowls, or anywhere else where drainage could pose an issue.

The reality is that not all facilities have adequate floor drainage to handle all the excess and waste water generated during cleaning. This is where sump sinks come into play, providing a solution to this common challenge.

Excess liquids are often directed from the main sink to the sump sink through a PVC or copper pipe. It's crucial for sump sinks to be equipped with a strainer to prevent large particles and debris from clogging the drain. A blocked drain can lead to significant problems and costly repairs if not addressed promptly.

Moreover, slips can be a real hazard in the workplace, but they can be mitigated by using proper drainage equipment. Always prioritize worker safety.

### Are Most Sump Sinks Made of Stainless Steel?

While we highly recommend using stainless steel troughs or drains when dealing with excess liquids, sump sinks can also be made from basic plastic. However, plastic is far less durable and doesn’t withstand long-term wear and tear. Over time, plastic can crack and warp, resulting in unreliable drainage. Plastic sump sinks will need replacing much sooner than their stainless steel counterparts. Although the upfront cost of plastic may be lower compared to stainless steel, it's essential to consider the long-term benefits of investing in a more durable option.

### IMC Model #FDSS – The Ultimate Sump Sink

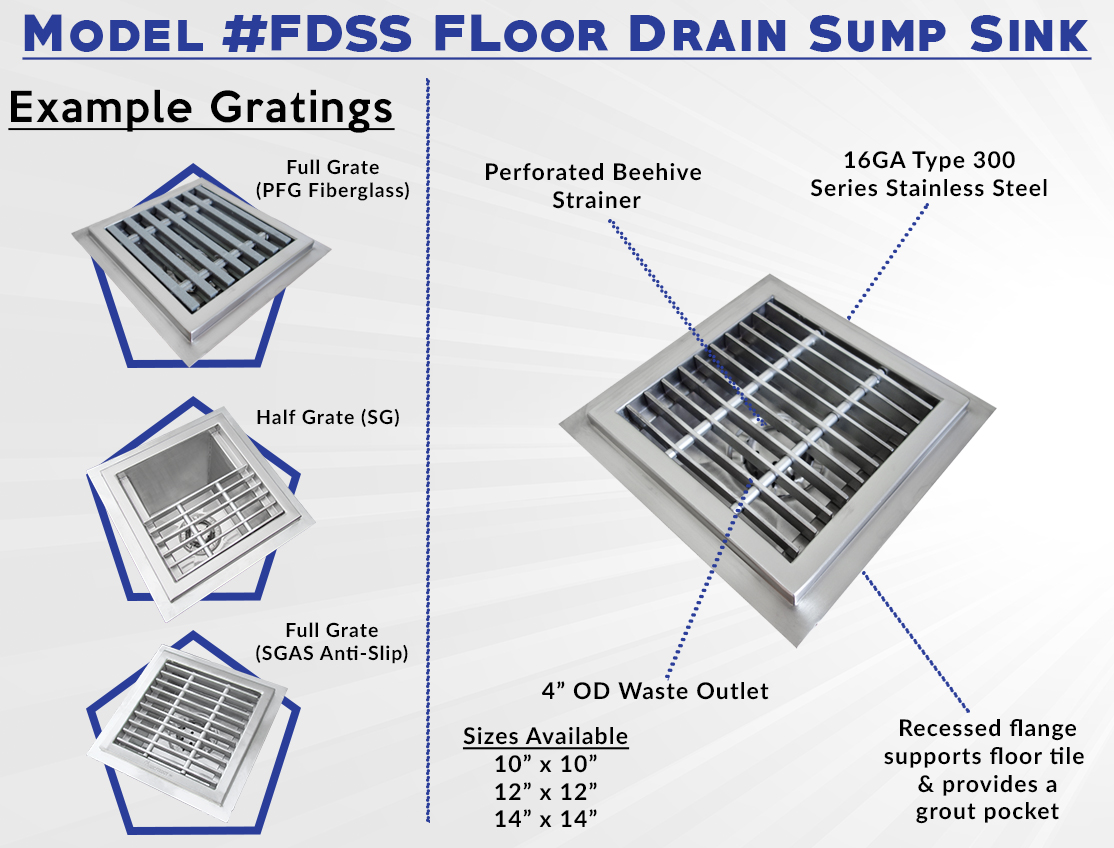

IMC/Teddy offers a premium sump sink, Model #FDSS. Constructed from 16-gauge type 300 series stainless steel, FDSS is available in three square sizes: 10"x10", 12"x12", and 14"x14". The standard depth is 4 inches.

FDSS can be fitted with various stainless steel or fiberglass gratings. A recessed flange and 1-inch deep ledge secure the grating in place. Gratings are available in half, three-quarters, and full sizes depending on the type of pipe you plan to use.

FDSS is also 100% NSF certified, making it safe for use in all commercial environments. Here’s a closer look at Model #FDSS:

IMC understands the importance of proper drainage in commercial settings. A dependable sump sink is essential when paired with a primary sink if floor drainage is insufficient. While cheaper alternatives exist, nothing compares to the long-term reliability and durability of a stainless steel sump sink. For more information on IMC’s floor troughs and drains, click [here](#).

---

*Disclaimer: The views and opinions expressed in this article are those of IMC/Teddy. Our content is intended for informational purposes only. If you'd like to feature this post on your website, please contact IMC/Teddy directly. Thank you.*

---

**Sharing Options:**

Share on Facebook | Share on Twitter | Share on LinkedIn | Share on Pinterest

Mushroom Sauce,Spicy Mushroom Sauce,Garlic Flavor Chili Sauce,White Quinoa Grain

Shanxi Fret International Trade Co.,Ltd , https://www.fretfruit.com